8 awesome Océ innovations

You may have heard of Copy Press, CrystalPoint and Radiant Fusing. But there are also lots of lesser-known innovations that make Océ products shine. Here are 8 examples of great Océ innovations at work, however small they may seem.

“Air guidance” for Light Weight Media

Black & white printing on Light Weight Media (LWM, 40–50 gsm plain paper) is considered a fast-growing segment. Print applications include technical and medical leaflets, but mainly involve books. LWM are very fragile and difficult to handle. Up till now, no printer was able to process LWM.

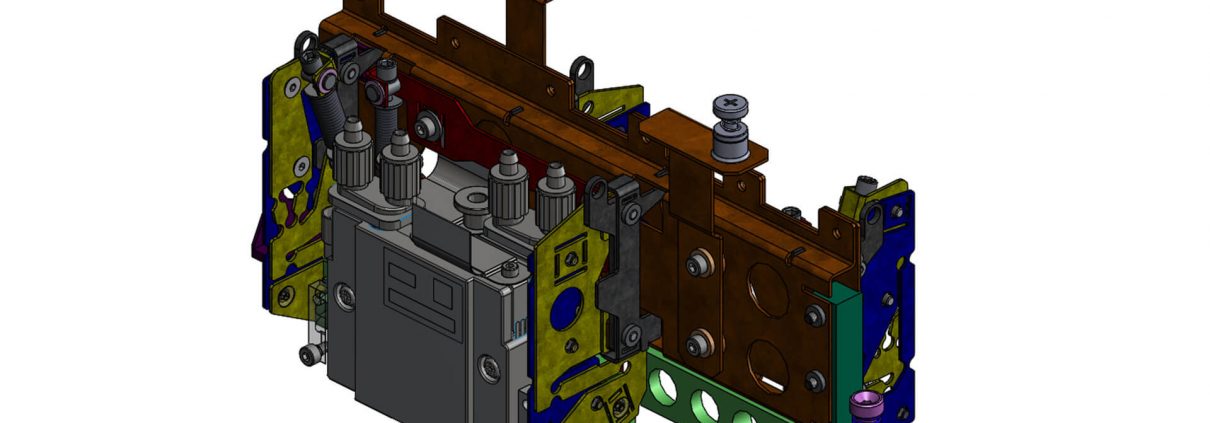

In order to make printing on LWM feasible for the Océ VarioPrint 6000, several modifications have been developed: ultra-high-precision parts, to avoid wrinkles, and a so-called “air guidance system”, to ensure the extremely high reliability of the Océ VarioPrint 6000, even for these very fragile media.

Developed by Océ in Venlo, the Netherlands

Pause function

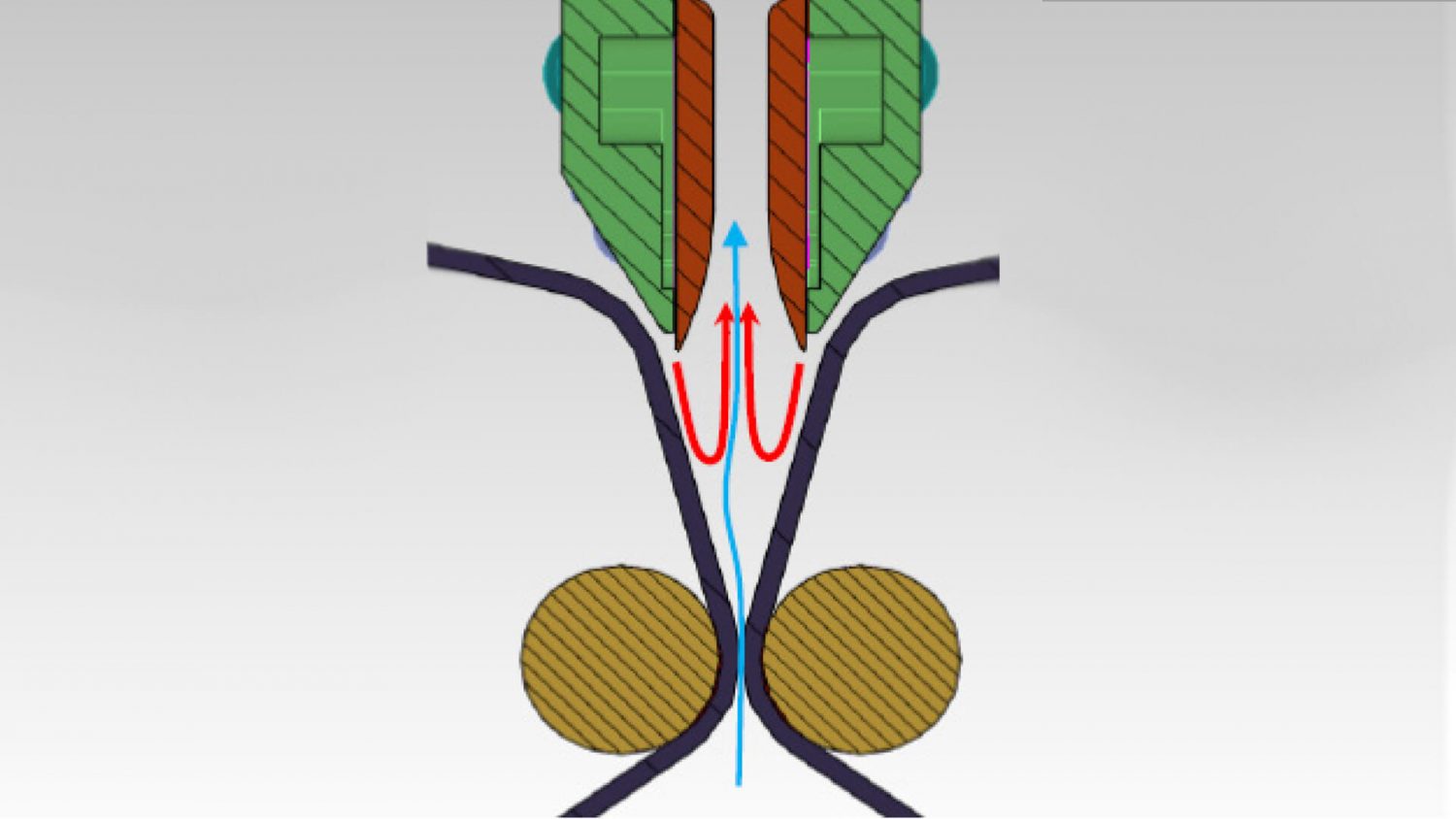

Registration errors (visible shift between colors) occur during the pause between heads that have already printed and those heads that will print after the stop. This print damage occurs due to undesired paper movement under the heads, caused by swelling of the paper while stationary.

Thanks to smart adjustment of web tension in pause mode, registration errors can now be minimized. The pause function allows customers to stop and run the web again, while maintaining print quality. This unique Océ innovation helps customers avoid paper waste and saves precious time.

Developed by Océ in Poing, Germany

Océ Pixel Link with prefire

![]()

Every printer has to transfer images to the printhead. Océ Pixel Link (OPL) has been developed as part of the SRA controller, to achieve this. OPL consists of 3 parts: a PCIe adapter card, the printhead controller board, and the fiber optical link connecting the 2 components. The printhead controller board adapts the data path to the specific printhead and includes functionality like prefire. Prefire is a method to refresh the ink in the printhead nozzle, in order to prevent the ink from drying out.

The advantages are scalability and the possibility to adapt the SRA controller to new printheads quickly. The new technology is used in the Océ ColorStream 3000/3000Z/6000, the Océ ProStream 1000, and shared with the Océ VarioPrint i300.

Developed by Océ in Poing, Germany

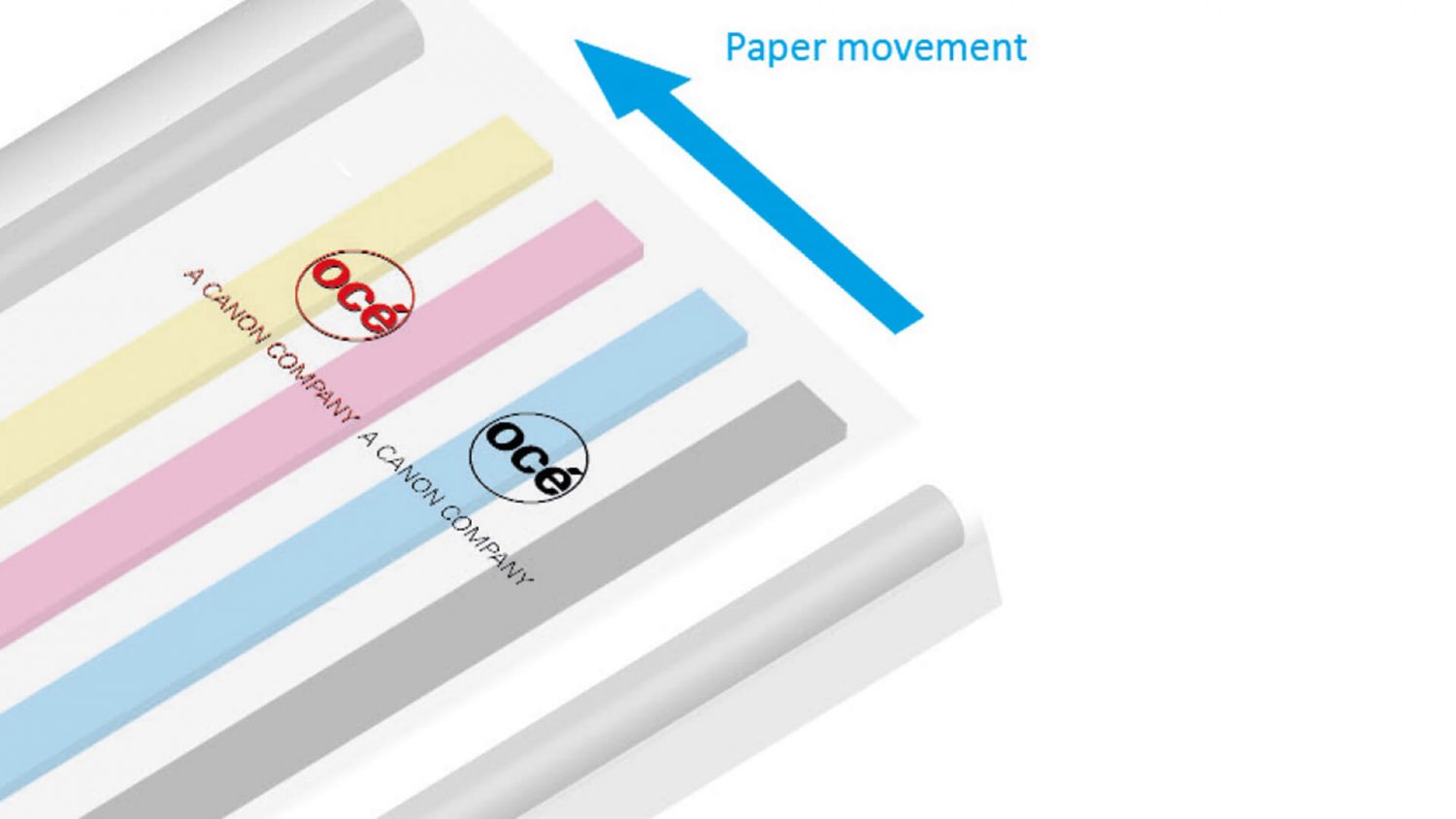

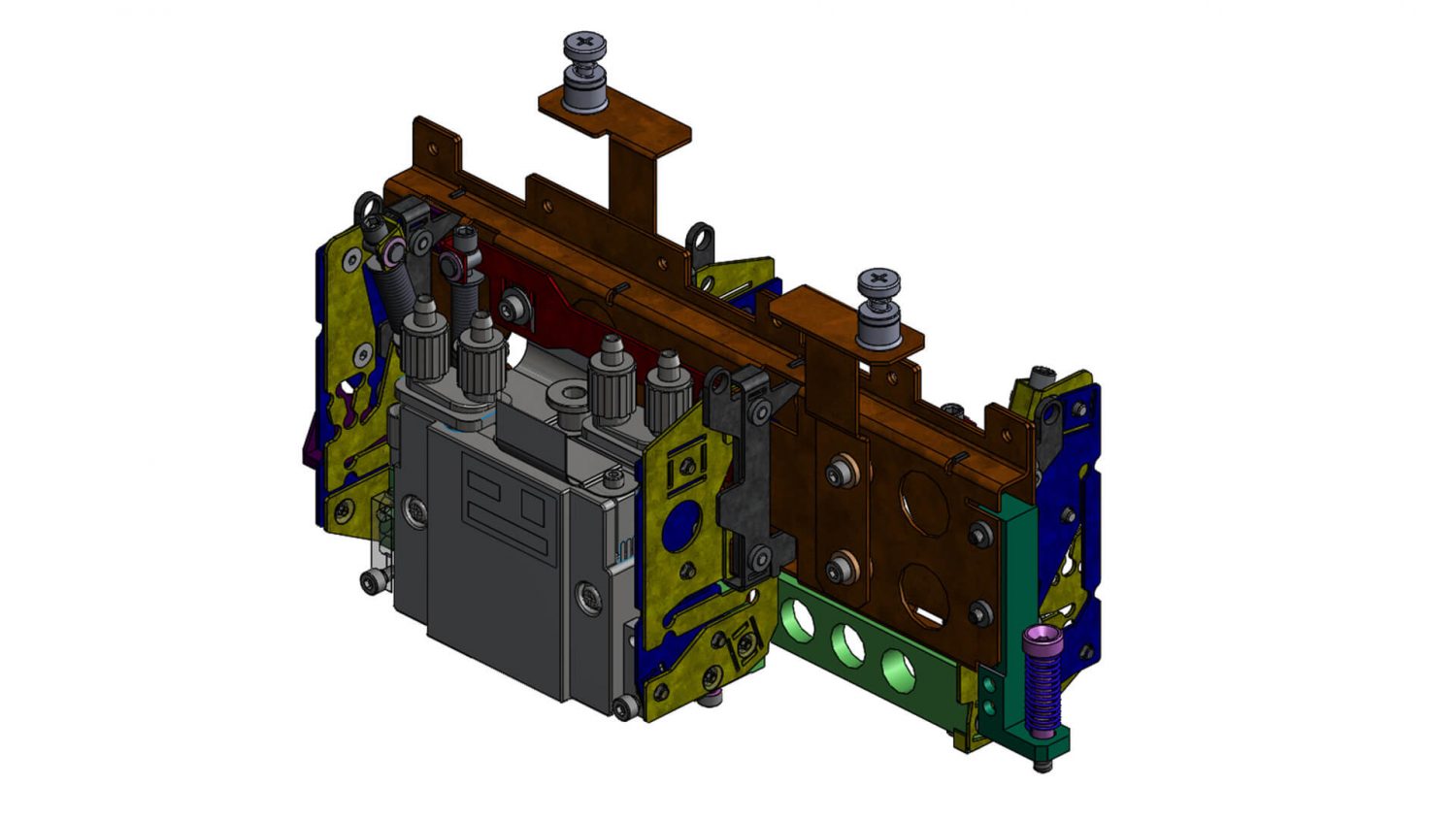

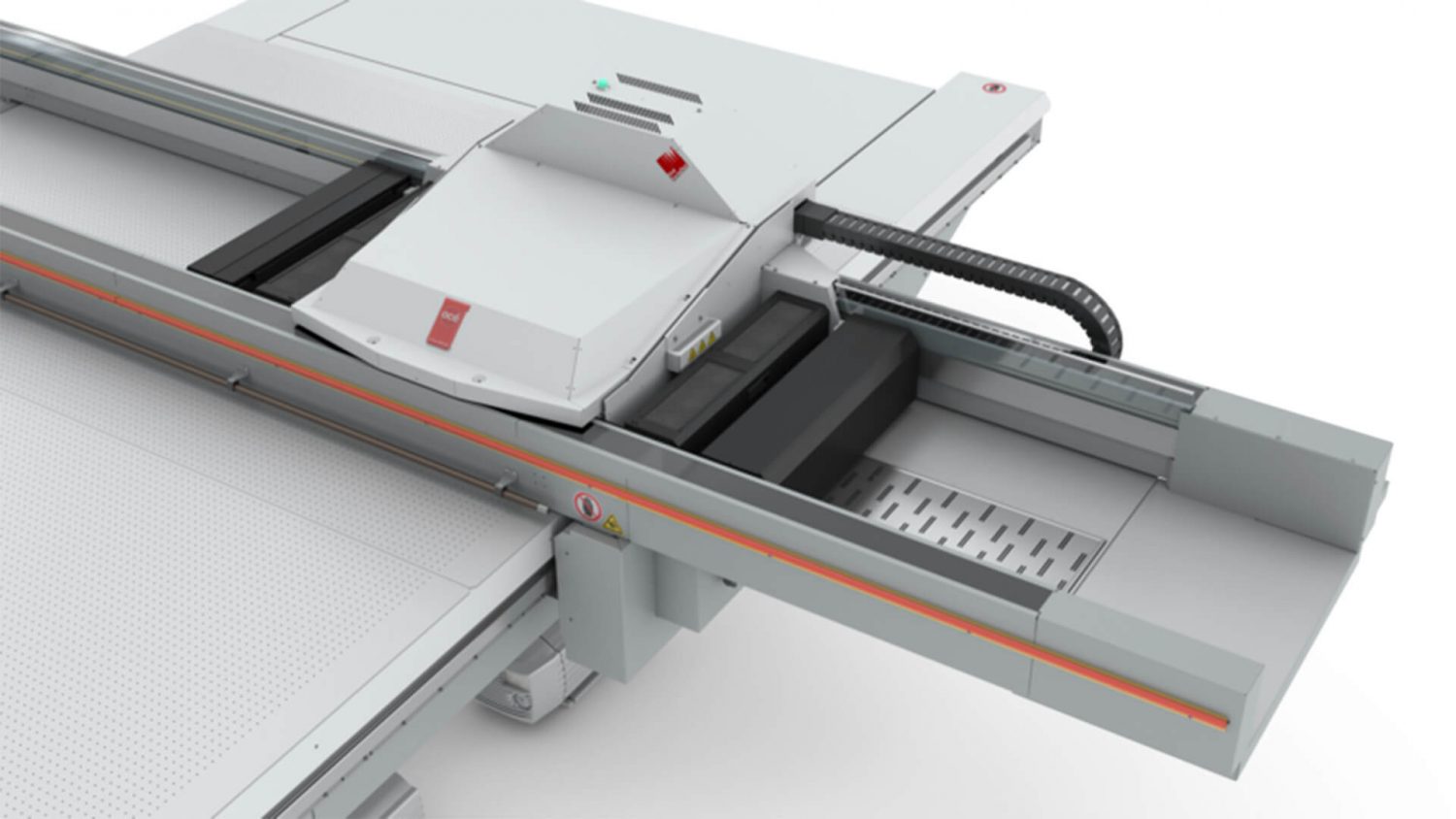

Micrometer-accurate printhead positioning

The Océ flexure-based printhead mounting is a major improvement over previous designs. The flexures remove the friction, backlash and hysteresis from the positioning adjustments, while the screw pitch and lever ratios provide the micron-level accuracy needed. This, combined with feedback from the vision system, results in an alignment that converges quickly and is stable over time. This innovation is used in Océ Arizona printers.

Developed by Océ in Vancouver, Canada

Machine vision

The integrated machine vision system makes hundreds of thousands of extremely accurate drop placement measurements. This rich information is crucial to determine the best positioning of all printheads in relation to each other as well as to the motion system. The system also makes it possible to measure the mechanical characteristics of each individual machine and correct for variations.

The combination of the flexure and vision systems results in superior image quality over the entire flatbed print area for high-productivity printers using up to 42 printheads. If a printhead needs to be replaced during the printer lifetime, the machine can be brought back to the original factory quality level. This system is used in Océ Arizona printers.

Developed by Océ in Vancouver, Canada

PRISMAlytics dashboard

The PRISMAsync dashboard helps Océ customers increase the productivity of high-volume printers. It gives insight into the accurate status of the productivity KPIs. It also gives hints about the areas where print floor managers can improve the workflow and save costs. The data from the engine is used to calculate where improvements can be made. Océ has a lot of machines in the field that generate lots of data. The PRISMAsync dashboard ensures this data is analyzed and displayed in a useful and clear way. Océ uses the latest Microsoft software, and the dashboard is fully hosted in the cloud. It’s available for all PRISMAsync devices, but is currently only relevant for high-volume engines.

Developed by Océ in Venlo, the Netherlands, Créteil, France, and Timisoara, Romania

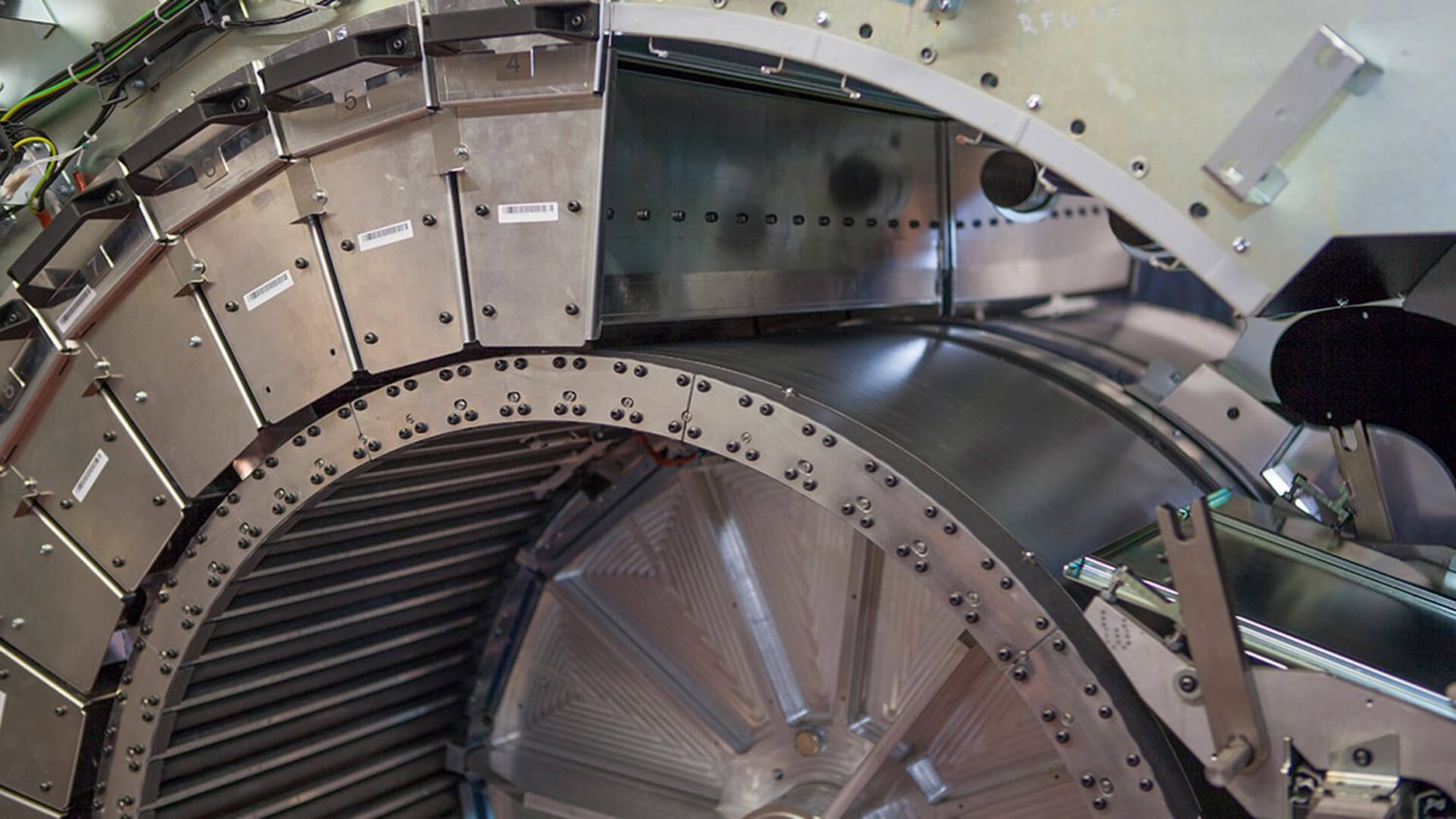

iQuarius Drying Drum

Used in the Océ VarioPrint i-series. The drum uses infrared heating, air and a moderate drying temperature, to minimize paper deformation while still delivering a robust drying result. Vacuum suction holds sheets tightly on the drum, ensuring accurate transport and flat sheets, no matter how much ink is on the paper. This impressive drum stops people in their tracks when it’s shown during a demo. The drum is a crucial part of Océ iQuarius Technologies, a set of innovations that enable high-speed inkjet printing on sheets: reliable, productive and with high quality.

Developed by Océ in Venlo, the Netherlands

Vibrating toner bottles

Toner is a miraculous material. It consists of very small particles. If you let a bottle of toner stand for a few days, the particles stick together and the volume reduces considerably. If you shake it, it “airs”, and the volume is large again. When the volume is large, it resembles a fluid and so it’s easy to empty a bottle. If the powder settles, it’s as solid as a rock. So to refill toner, Océ used to have very large bottles, so that the toner could be “aired” and regain its volume. The implications were that the company was shipping large bottles that were only 1/3 full.

The vibrating toner bottle innovation means it’s no longer necessary to “air” the toner, and so smaller bottles can be used. After putting the toner bottle in place, a mechanism in the printer starts to vibrate. The vibration ensures that even “solid, unaired” toner starts pouring out.

Developed by Océ in Venlo, the Netherlands

Related Posts

Canon receives three Keypoint Intelligence awards in Buyer’s Lab round-up

21/10/2020 NewsKeypoint Intelligence has recognised the advances that Canon has made in production print with the BLI Outstanding Innovation Awards for three Canon products: the sheetfed inkjet varioPRINT iX-series, the ProStream 1800 web-fed inkjet printer and the Arizona 2300 flatbed printer series.

Learn moreOcé in Dutch R&D Top 10

12/07/2018 NewsIn May 2018, the Dutch magazine Technisch Weekblad published their yearly R&D Top 30 for companies in the Netherlands. The top R&D investor in the Netherlands is ASML. Philips takes the second place. The list is rounded off with Océ at number 10.

Learn more