Canon Expands Portfolio of Large Format Graphics Production Printers with 3.4m Colorado XL-series Powered by its Unique UVgel Technology

Venlo, 30th September 2025 – Canon today announces the Colorado XL-series, a new platform of 3.4m/11ft printers that extends the proven advantages of Canon’s UVgel technology to the 3.2m/10ft graphics market. Available in hybrid and roll-to-roll configurations, the modular, field upgradable platform powered by UVgel technology delivers great versatility and exceptional productivity for both flexible and rigid media applications.

The Canon Colorado XL-series offers excellent flexible and rigid media handling with one UVgel 860 gel set

The Colorado XL-series comprises two easy-to-operate models: the Colorado XL7 roll-to-roll printer and Colorado XL7 hybrid printer. Like the Colorado M-series, the Colorado XL-series modular platform design ensures a future-proof investment: customers can start with the configuration that meets today’s business needs and, as requirements grow, add capabilities through field upgrades, such as a dual roll option[1] that allows two 1.6m rolls running side by side to be tensioned individually.

The Colorado XL-series brings the benefits of UVgel to a new market segment with exceptional application versatility across a comprehensive range of media – from banner, paper, vinyl and films to textiles, heat-sensitive materials, foam board, fluted polypropylene, acrylic, aluminium composite boards and cardboard – providing the flexibility to tackle diverse customer requirements. With print speeds of 70m²/753ft2/23 boards[2] per hour in quality mode, 106m2/1,140ft2/35 boards per hour in production mode and up to 211m²/2,271ft2/70 boards per hour in express mode, the system delivers the productivity needed for demanding production environments while accommodating substrates up to 52mm/2 inches thick for rigid applications.

Representing the next major milestone in Canon’s large-format graphics evolution, the Colorado XL-series builds on the success of the Colorado M-series, which has transformed roll-to-roll printing for thousands of customers worldwide. Conceived to help print service providers, and print factories expand and improve their capabilities and enter new high-value market segments, the new platform includes multiple technology innovations.

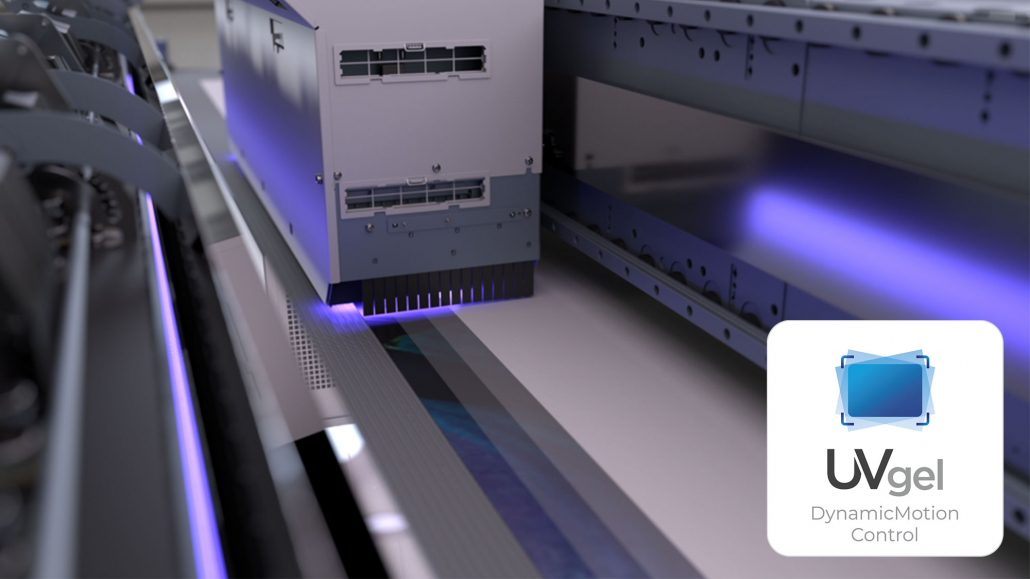

UVgel DynamicMotion Control carriage with UVgel 850 printheads deliver precise positioning for consistent quality

The Colorado XL-series introduces the UVgel 860 gel set, which has been optimized to cover a wide variety of both rigid and flexible applications. It also provides the proven benefits of UVgel: odourless and instant-dry prints, high mechanical and chemical robustness, dimensional stability due to low-temperature curing, excellent colour consistency, TPO[3]– and VCL[4]-free, and matte and gloss finish without the need of a separate varnish.The platform also includes new UVgel 850 PrintHeads. Designed for the productive printing of high-quality, large-format graphics, each printhead has 4,544 nozzles and features automated built-in nozzle performance monitoring and compensation. A single printhead supports two colours simultaneously, so that only two printheads are required to print CMYK, plus an optional third if white is needed. Additionally, the Colorado XL-series has an agile and precise printhead carriage that features UVgel DynamicMotion Control to ensure exceptional print quality even with challenging media. Machine vision technology actively tracks any micro movement of the media while the carriage is travelling, UVgel DynamicMotion Control recalibrates the printhead positioning on-the-fly for unmatched precision and alignment of print passes, ensuring flawless results even at high speeds.

Taking the UV LED curing process to the next level, the Colorado XL-series introduces UVgel FullBeam Curing. This technology uses a unique 3.4-metre-wide LED curing array that, combined with an ingenious mirror system, delivers consistent UV light dosing across the entire print width, guaranteeing exceptional print uniformity over large surfaces, and enabling a wider colour gamut.

UVgel FullBeam Curing technology enables exceptional quality across the entire 3.4m print width

Automatically detecting and correcting the media positioning, the UVgel TRIdrive vacuum belt system features three interactive rollers and multiple powerful vacuum zones that reduce wrinkling and skewing and result in highly repeatable media transport through the printer, ensuring accurate positioning both longitudinally and laterally and enabling razor-sharp applications. This advanced self-steering belt system provides unparalleled stability and control when handling a variety of media types, from stretchable flexible materials to challenging rigid substrates. The UVgel TRIdrive system provides a number of additional benefits for flexible media: automatic loading and straightening even for less experienced operators, reduced media waste by printing on the leading edge, and unattended printing through automatic tension adjustment on the feeding and take-up spindles. By optimising the media transportation and tensioning, the system enhances accuracy and reduces errors in complex printing scenarios. In addition, the vision-based Smart Guided Workflow provides operators with an intuitive media loading procedure that allows multiple boards[5] to be loaded side-by-side and independently of each other.

Optional features for the Colorado XL-series include UVgel White for hassle-free white printing, FLXfinish+ for creative effects using matte or gloss or mixed matte and gloss on the same print without additional varnish, and FLXture for textured finishes that mimic materials like leather, wood or fabric.

Sustainability and cost-effectiveness have been built into the Colorado XL-series from the ground up. Low VOC emissions and a GREENGUARD Gold certification ensure suitability for sensitive indoor environments. Combined with low energy and minimal gel consumption, automated quality control systems and features designed to reduce waste, such as a two-litre bag of UVgel in a recyclable box, the system delivers an attractive total cost of ownership. The Colorado XL-series supports eco-friendly media including PVC-free and paper-based substrates, while a multi-level service concept—from automated maintenance to remote support—minimises environmental impact and maximises uptime.

Peter Wolff, Chief Marketing Officer and Senior Vice President at Canon Production Printing, comments: “Large format print providers in the 3.2m graphics market are looking for systems that deliver high productivity, versatile applications, and reliable quality while addressing the challenge of finding skilled operators. The Colorado XL-series meets all these needs with an advanced platform that combines the significant advantages of our unique UVgel technology with extensive automation and a modular design that can grow with a customer’s business.

“With features such as one-day operator training, automated maintenance and Smart Guided Workflow for automatic image positioning and easy media loading, we’re helping our customers overcome operational challenges while expanding into high-value applications. We want every wide format customer to reap the benefits of UVgel technology, whatever the application, and the Colorado XL-series will help them to do exactly that.”

The Colorado XL-series will be available from the beginning of 2026 via Canon’s direct sales organisations as well as from accredited partners.

For more information about the Colorado XL-series, please visit the product page.

[1] Available with R1.1

[2] Board size = 122cm x 244cm (48 inches x 96 inches)

[3] TPO: Trimethylbenzoyl Diphenylphosphine Oxide

[4] VCL: Vinylcaprolactam

[5] From release 1.1 onwards