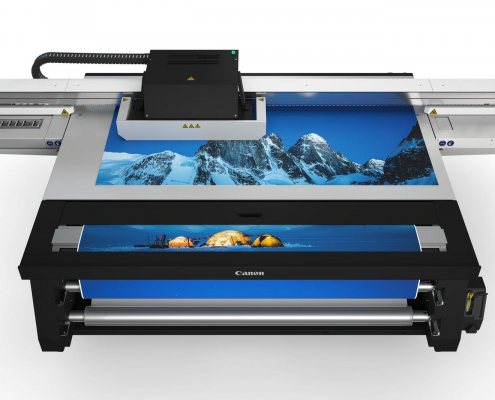

Arizona FLXflow technology

The Arizona 1300 and 2300 series are built around Arizona FLXflow technology that revolutionizes the way we look at flatbed table architecture, to enable easy to use, versatile and productive printing. Say goodbye to costly masking: Arizona FLXflow technology introduces an impressive airflow technique combined with a zone-less, multi-origin table layout, supported by easy-to-use pneumatic registration pins. This results in less masking, easy and hassle-free job switching and versatile, accurate and productive multi-board or double-sided printing. Arizona FLXflow technology gives you practically no need for masking, so switching between jobs is quick and simple. Fewer process steps lead to fewer mistakes and greater productivity.

FLXflow in a nutshell

Offering a unique, patented way not only to hold but also to float the media, FLXflow comes with three functionalities – Hold, Float and Instant Switch – allowing users to move heavier and irregular-sized media faster and more easily around the table. The Hold functionality, a feature of the original FLOW technology, works by keeping the media in place with a patented airflow technique. Using automatic measurement and adjustment of airflow levels to firmly and accurately hold various types of media in place, the functionality results in flexible positioning with far less masking.

The new Float functionality is an optional feature that pushes air from the table upwards to create a cushion, enabling the easy positioning of heavy or challenging substrates and reducing the risk of media damage or waste. It also results in the smoother registration of all types of media, with a ‘floating without drifting’ functionality enabling several pieces of media to be precisely positioned at the same time. The Instant Switch functionality allows the operator to easily change from Hold to Float by using the foot pedals for simple operability of the printer, making it easy to remove media from the table.