UVgel

One technology. No compromise.

One technology. No compromise.

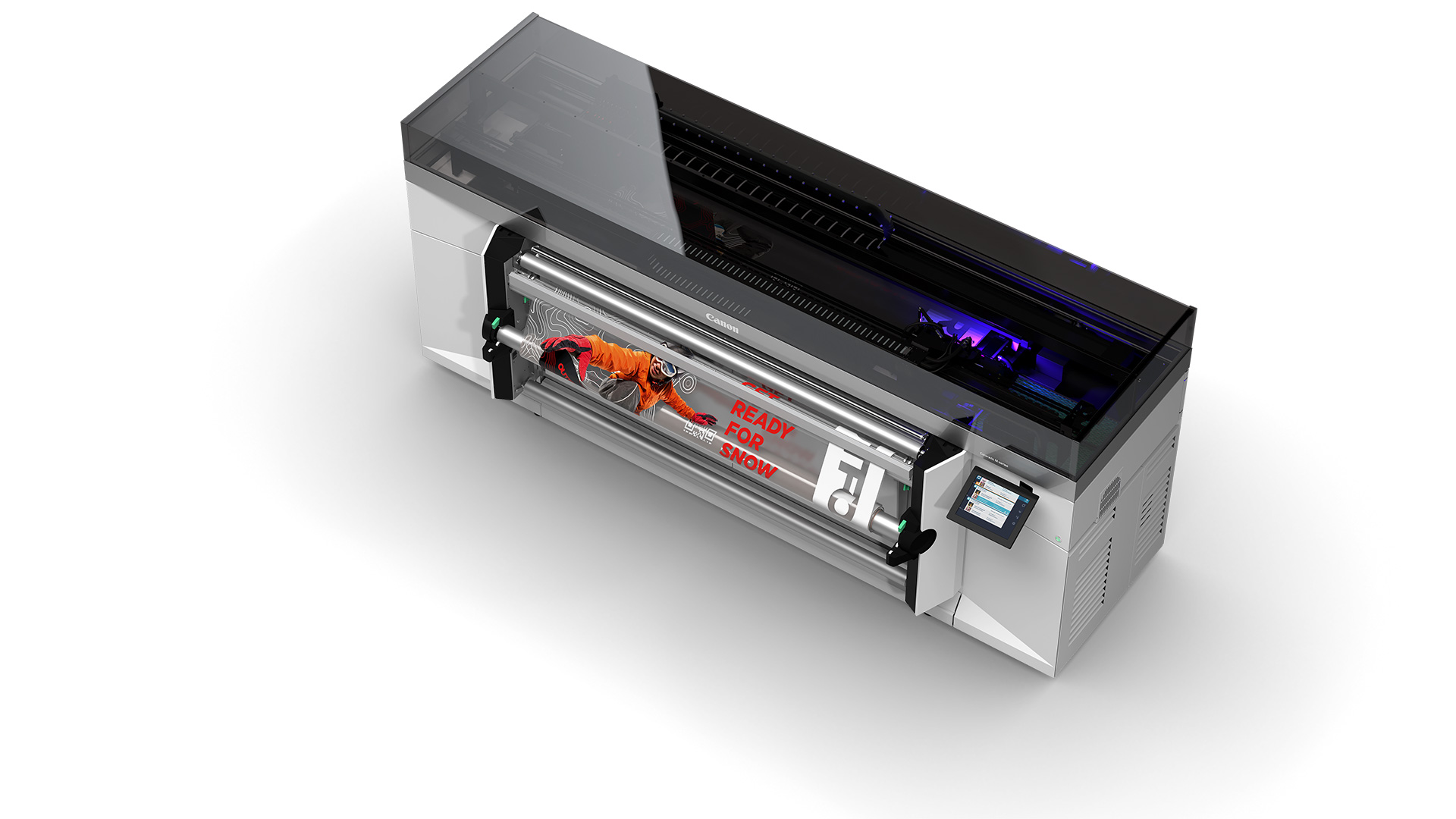

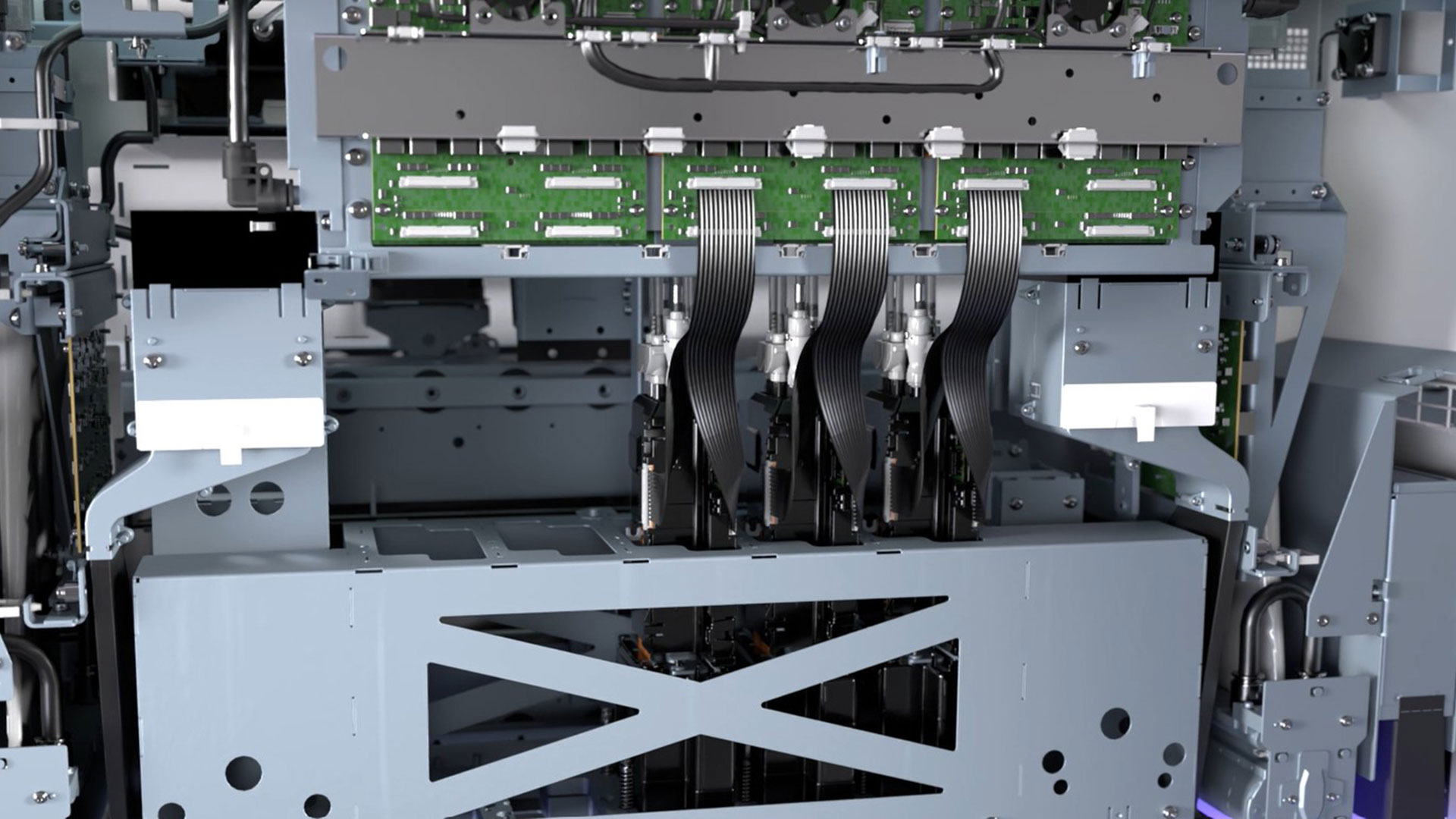

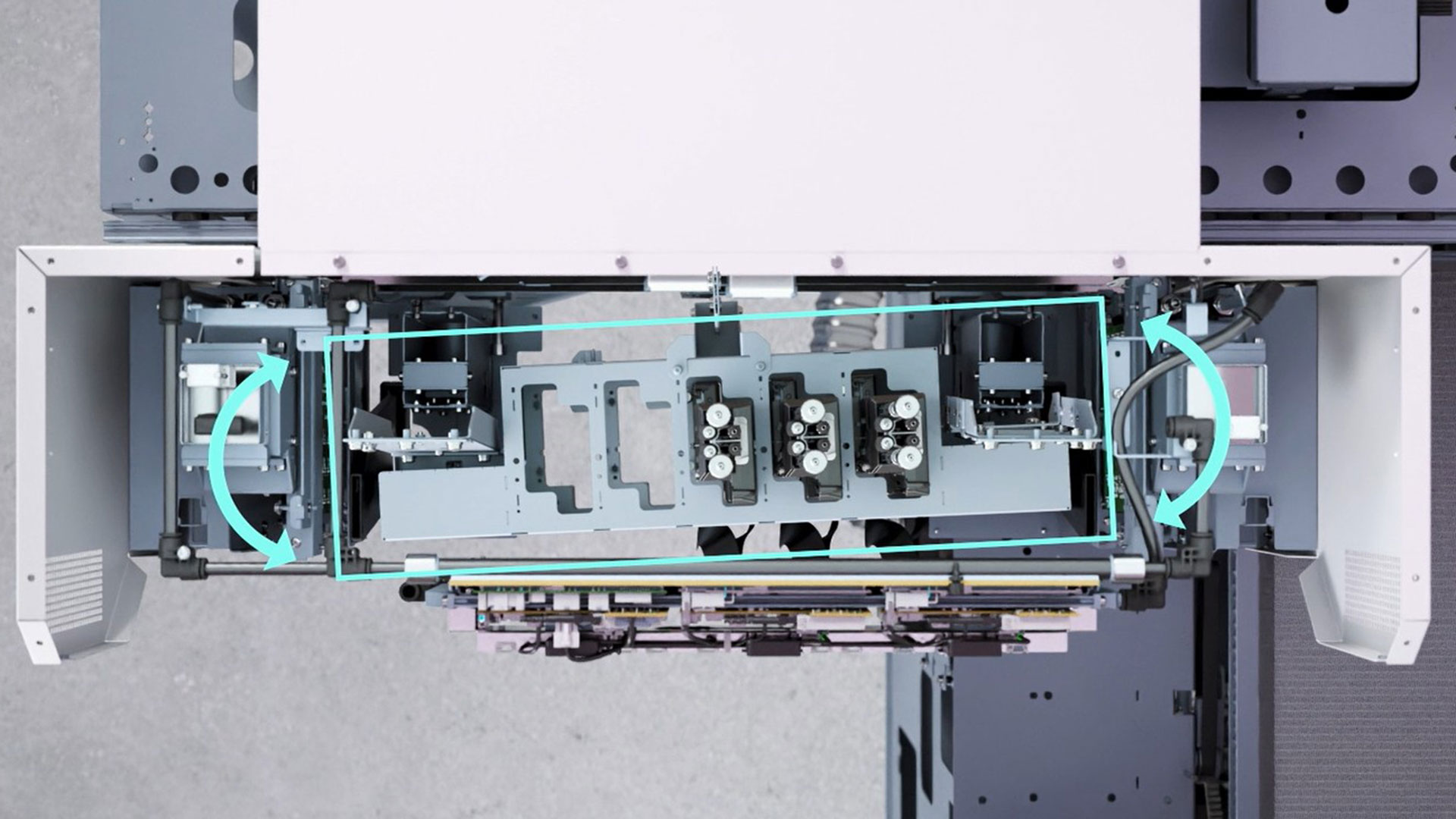

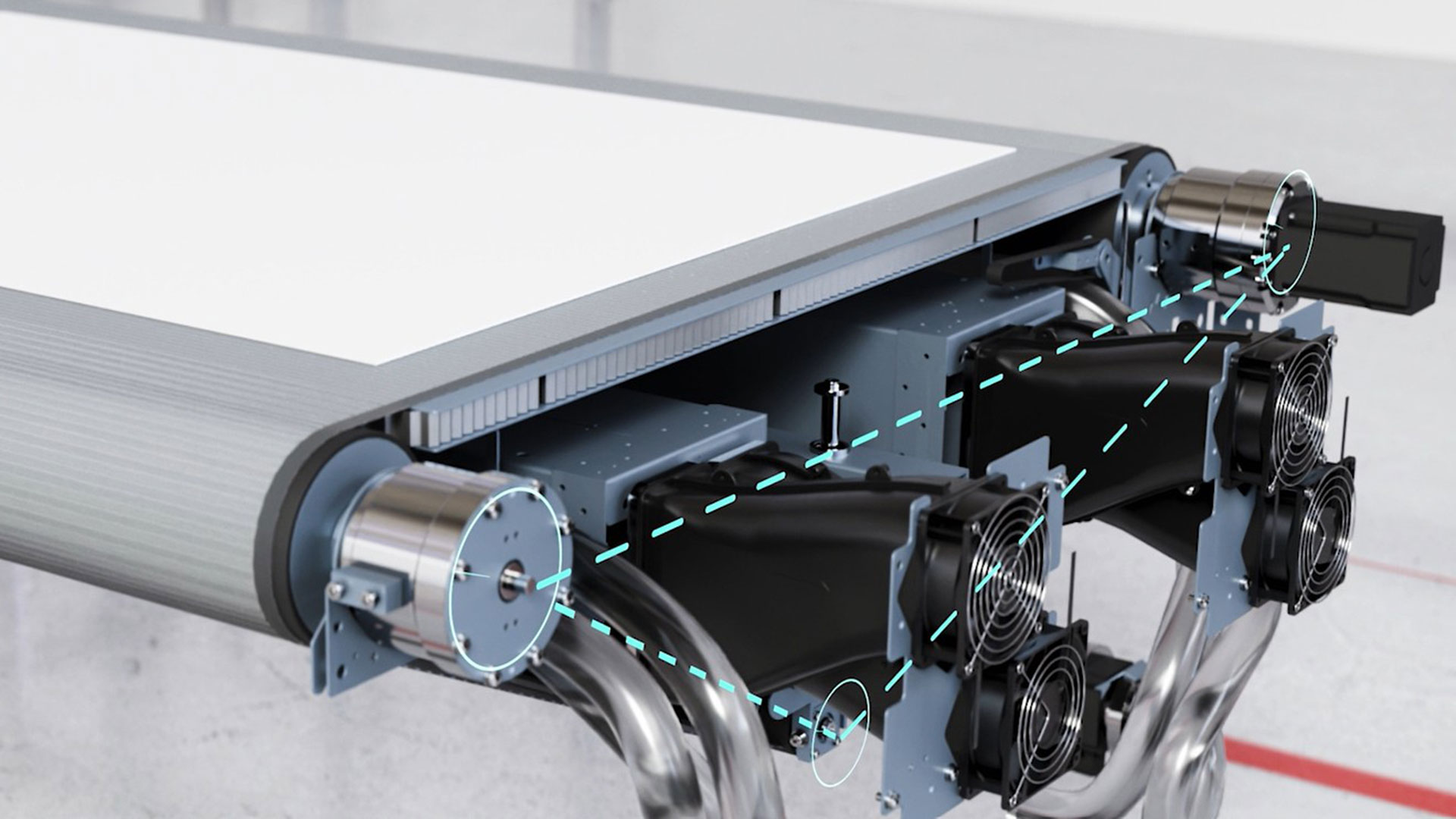

Canon UVgel technology comprises several specially-developed elements that combine to achieve a process that retains the advantages of prevailing printer technologies, while eliminating many of the compromises.

The key to Canon UVgel technology is the fact that the ink is essentially a gel, developed according to UV curing principles. The simplified stages of the Canon UVgel printing process are as follows:

FLXfinish+ is the unique ability to print matte, gloss or mixed matte and gloss in one go, shaking up the world of large-format graphics. Made possible by the gelling characteristics of UVgel ink, FLXfinish+ allows you to add a velvety matte finish to interior décor products, a brilliant gloss finish for display prints, or unique combinations of the two to create attention grabbing visuals, with perfect registration and without the need for an extra printhead or ink channel.

With only one click of a button, FLXfinish+ helps you improve the value of your products without increasing the complexity of your work.

With FLXture, you can add subtle surface detail to your prints, creating a luxurious and intriguing feel for your products. You can create these creative print applications with an easy-to-use recipe in our PRISMAguide XL software. It will intelligently prepare layers of UVgel ink to stack on top of each other, unlocking a next-level sensory experience.

Design beautiful, high-value packaging, attention grabbing labels and easily enhance your products with new surface textures without complicated material combinations. Whether you want a subtle background texture, elegantly embossed lettering or a bold futuristic pattern, you can print it on your Colorado series printer. A delight to the senses, at the touch of a button.

Our highly productive UVgel white works as any other colour, with no extra maintenance. It’s up to 3 times faster than comparable technologies even for multilayer modes and has high ink efficiency, resulting in low ink consumption.

The printed UVgel white keeps its colour over time. It has the flexibility that you expect for all your applications, and lends itself easily for perfect layering – even up to five layers – to be cut, stretched and finished, directly after printing. And the automated maintenance features of the Colorado series keep the ink and nozzles ready to print all day, every day.

Printing UVgel white with the Colorado series uses significantly less ink and provides less waste. There is no separate action, set-up or maintenance needed to print an application that includes white ink. With productive print modes that are realistic for a high-quality operation, and no hidden costs, applications with white ink are a great way to increase your profit margins.

ClearConnect

ClearConnect