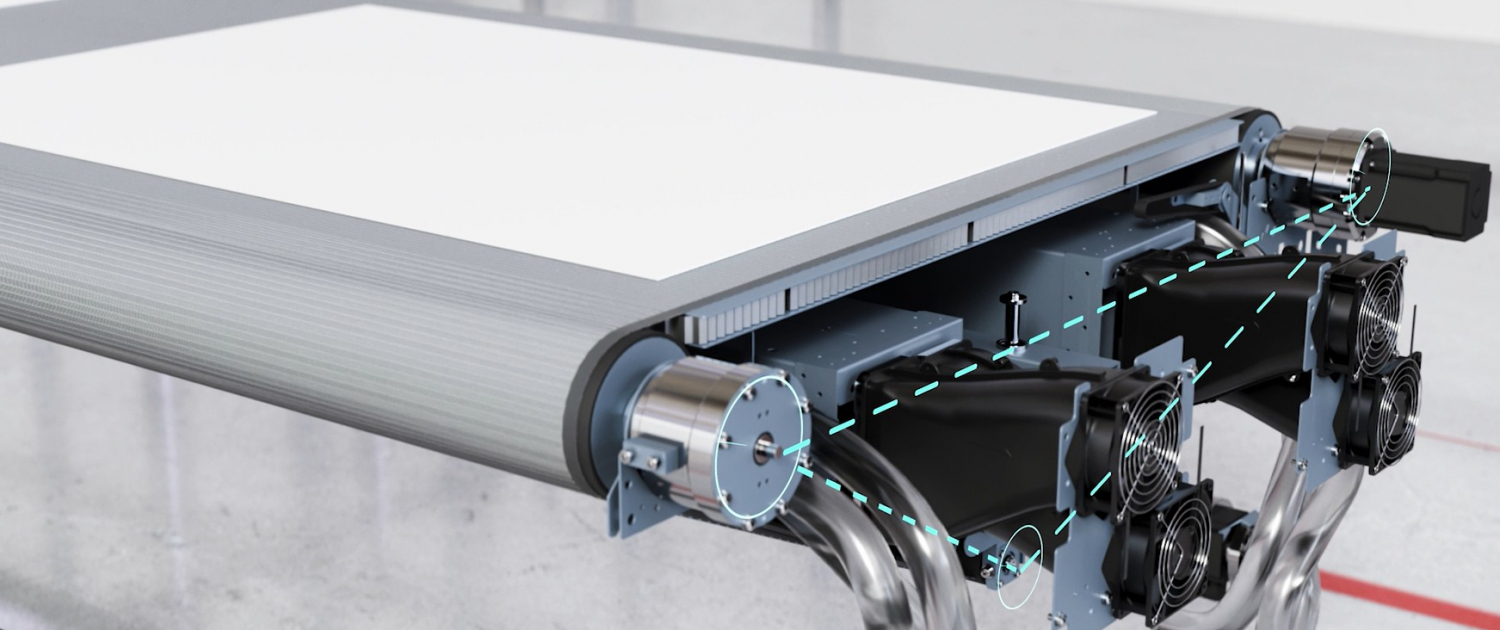

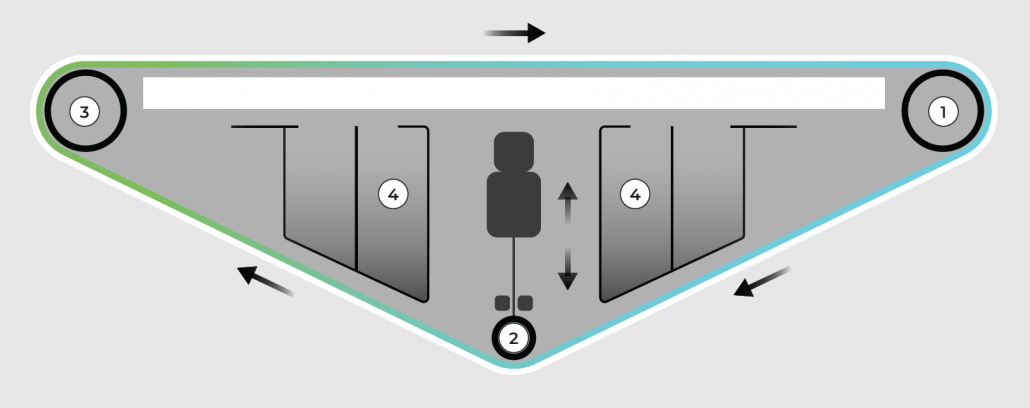

UVgel TRIdrive vacuum belt system

The Colorado XL-series introduces our unique UVgel TRIdrive (Three Roller Interactive) vacuum belt system. It’s designed to help limit errors at job start-up, for easy loading, highly precise media positioning and reliable unattended printing that helps users create razor-sharp applications that truly impress.

Accurate placement and transportation

The UVgel TRIdrive vacuum belt system features three interactive rollers and multiple powerful vacuum zones that automatically detect and correct the media positioning to reduce wrinkling and skewing.

Its advanced, self-steering belt system provides unparalleled stability and control when handling a variety of media types, from stretchable flexible materials to challenging rigid substrates. The UVgel TRIdrive delivers a number of additional benefits for flexible media.

These include:

- Automatic loading and straightening for reliable operation, ideal for less experienced operators

- EdgeForward printing that promotes media savings

- Unattended printing through automatic tension adjustment on the feeding and take-up spindles