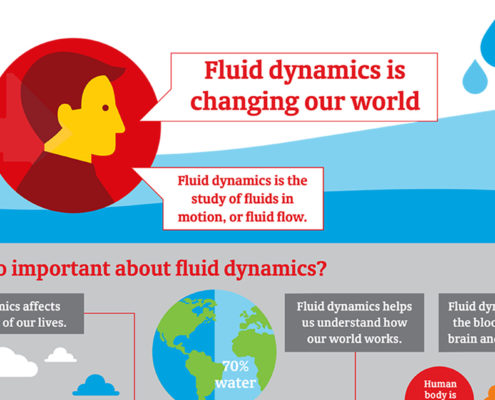

Home / Fluid Dynamics / From the world of print to printing the world

https://cpp.canon/app/uploads/2018/05/Infographic-Fluid-Dynamics.jpg

1080

1920

Michel van der Wal

Michel van der Wal2018-07-23 10:40:582019-02-18 13:31:53Infographic: fluid dynamics is changing our world

https://cpp.canon/app/uploads/2018/05/Infographic-Fluid-Dynamics.jpg

1080

1920

Michel van der Wal

Michel van der Wal2018-07-23 10:40:582019-02-18 13:31:53Infographic: fluid dynamics is changing our world