“Together with the universities of Twente and Eindhoven, we study fundamental questions like drop formation, as well as the interaction between ink or more complex fluids with different types of substrate. This research will help us to make inkjet printing even faster and more accurate and to develop new applications for inkjet technology.”

Complementary to Canon

Canon acquired Océ in 2009. In a way, this confirms that the choice to focus on inkjet technology was the right one. “Canon is one of the inventors of inkjet technology, back in the seventies and eighties”, Slot explains. “Océ and Canon complement each other. Our technology platforms differ. Canon focuses on bubblejet, a technology which is based on thermal energy boiling the ink for jetting. Our technology is based on the piezoelectric effect to deform the ink channels for jetting. These combined technology platforms make Canon unique.

Worldwide, Canon is the only company that offers both technologies on a serious scale!” Wijshoff: “The strengths of bubblejet are well known and relate to low cost printheads and the ability to jet very small droplets. Océ will keep focusing on piezoelectric jetting, which allows for more freedom in designing inks for the new types of printers we have in mind. With piezoelectric jetting we are not limited to water based inks as is the case with bubblejet. At the same time, we work closely with Canon in areas of common interest, such as new printheads and ink.”

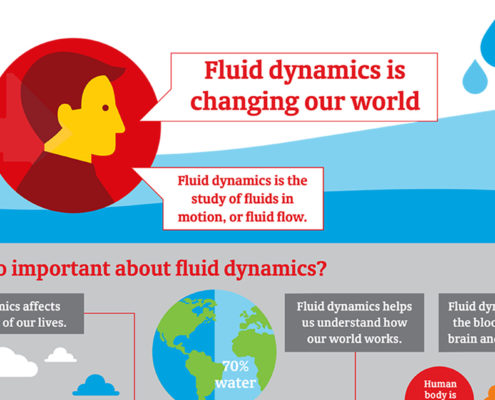

https://cpp.canon/app/uploads/2018/05/Infographic-Fluid-Dynamics.jpg

1080

1920

Michel van der Wal

Michel van der Wal2018-07-23 10:40:582019-02-18 13:31:53Infographic: fluid dynamics is changing our world

https://cpp.canon/app/uploads/2018/05/Infographic-Fluid-Dynamics.jpg

1080

1920

Michel van der Wal

Michel van der Wal2018-07-23 10:40:582019-02-18 13:31:53Infographic: fluid dynamics is changing our world